This morning my daughter had the call she was dreading. The anorexia has such a hold that her doctor now believes her health is "medically compromised". She has been admitted into hospital where they can give her 24/7 professional care.

Although admission was always on the cards if her condition did not improve, it still came as quite a shock to us all when she was given two hours to pack and present herself at the hospital. Whilst we all know this is for the best, it makes the transition no less difficult both for her and us, especially at Christmas.

I wish you a speedy recovery my love.

Saturday, 29 December 2012

Monday, 24 December 2012

Front brake pipes

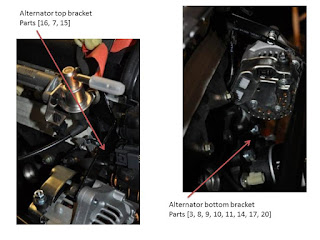

Alternator assembly

I thought this would be a five minute job - not quite because there are no drawings or instructions, just a number of brackets, bolts and washers.

I thought this would be a five minute job - not quite because there are no drawings or instructions, just a number of brackets, bolts and washers. I pinched this photo from Dave Smeaton's blog because I forgot to take a "before" photo (Thanks Dave - hope you don't mind). I have labelled the components so you can see where I think they all should end up. As with most of this build, I doubt there is a right and a wrong, but if it seems logical then it's probably OK.

Here is a photo with everything fitted so you can see the layout.

I fitted the tensioner first as this seemed the most straightforward and reduced the number of components left to choose from for the top and bottom bracket assemblies.

In order to fit the top bracket the inlet manifold had to come off first. On my Zetec the mounting hole was also being used for one of the engine winch eyes. As I am still using these winch points to move the front of car around the garage, I left the winch eye in situ.

The lower bracket uses the spacer [17] between it and the engine block. The alternator itself is held into the bracket with washers used as spacers.

Sunday, 16 December 2012

Near-side Panel and Suspension

Nothing much to say about the near-side that hasn't already been said for the off-side. The side panel went on fine - with a bit of fettling where it meets the back panel as I decided to build the back before the front. The suspension went back together without issue including IVA covers.

Whilst I had an open (and warm) tube of "black-glue" I thought I would bond the inner side panels. I decided not to rivet - these panels are not for strength or rigidity.

Whilst I had an open (and warm) tube of "black-glue" I thought I would bond the inner side panels. I decided not to rivet - these panels are not for strength or rigidity.

Whilst I had an open (and warm) tube of "black-glue" I thought I would bond the inner side panels. I decided not to rivet - these panels are not for strength or rigidity.

Whilst I had an open (and warm) tube of "black-glue" I thought I would bond the inner side panels. I decided not to rivet - these panels are not for strength or rigidity.Front Suspension

Its been a few weeks since I worked on the zero. One weekend was spent in Derbyshire in a superb chalet with great spa facilities for my daughters 18th birthday. I great family weekend. But unfortunately my daughter is not well at the moment. She has been diagnosed with Anorexia - a truly awful condition. You can't really comprehend the depth and scale of the physical and mental suffering this condition causes until you witness it at first hand. It is currently taking a huge toll, especially on my daughter, but also the rest of the family. No amount of support seems to be able to combat the torment that this disease delivers.

My Zero build is not a race and I am under no pressure to complete the car quickly, however it has now developed a further function, as a cathartic release for a few hours when I can.

Last Sunday I did find some time where I could concentrate on the Zero and lose myself in the build for a few hours. The off-side panel was bonded and riveted a few weeks back, so I thought I would re-assemble the front suspension and fit the IVA covers.

Last Sunday I did find some time where I could concentrate on the Zero and lose myself in the build for a few hours. The off-side panel was bonded and riveted a few weeks back, so I thought I would re-assemble the front suspension and fit the IVA covers.

The torque settings I had difficulty with. Having used the Haynes manual as a primary source, I then used the web to supplement this and common sense for the rest. When I asked GBS for the settings at the rear I surprisingly didn't get a straight forward list. Perhaps for fear of liability, I don't know. But I haven't bothered to ask GBS for the settings for the front. The settings I have used are in the Torque Settings page. These are for my reference only. I don't recommend these settings. As I have said before, it is not me that will be cornering hard in your car. You must decide the setting you use.

The torque settings I had difficulty with. Having used the Haynes manual as a primary source, I then used the web to supplement this and common sense for the rest. When I asked GBS for the settings at the rear I surprisingly didn't get a straight forward list. Perhaps for fear of liability, I don't know. But I haven't bothered to ask GBS for the settings for the front. The settings I have used are in the Torque Settings page. These are for my reference only. I don't recommend these settings. As I have said before, it is not me that will be cornering hard in your car. You must decide the setting you use.

I also fitted the brake pads into the callipers and the braided hoses to the side panel. I did have a little issue with the retaining spring on the brake pads. I couldn't find any information on how to assemble it, but eventually found a position that seemed logical, although it did keep shooting off.

I also fitted the brake pads into the callipers and the braided hoses to the side panel. I did have a little issue with the retaining spring on the brake pads. I couldn't find any information on how to assemble it, but eventually found a position that seemed logical, although it did keep shooting off.

My Zero build is not a race and I am under no pressure to complete the car quickly, however it has now developed a further function, as a cathartic release for a few hours when I can.

Last Sunday I did find some time where I could concentrate on the Zero and lose myself in the build for a few hours. The off-side panel was bonded and riveted a few weeks back, so I thought I would re-assemble the front suspension and fit the IVA covers.

Last Sunday I did find some time where I could concentrate on the Zero and lose myself in the build for a few hours. The off-side panel was bonded and riveted a few weeks back, so I thought I would re-assemble the front suspension and fit the IVA covers.

The torque settings I had difficulty with. Having used the Haynes manual as a primary source, I then used the web to supplement this and common sense for the rest. When I asked GBS for the settings at the rear I surprisingly didn't get a straight forward list. Perhaps for fear of liability, I don't know. But I haven't bothered to ask GBS for the settings for the front. The settings I have used are in the Torque Settings page. These are for my reference only. I don't recommend these settings. As I have said before, it is not me that will be cornering hard in your car. You must decide the setting you use.

The torque settings I had difficulty with. Having used the Haynes manual as a primary source, I then used the web to supplement this and common sense for the rest. When I asked GBS for the settings at the rear I surprisingly didn't get a straight forward list. Perhaps for fear of liability, I don't know. But I haven't bothered to ask GBS for the settings for the front. The settings I have used are in the Torque Settings page. These are for my reference only. I don't recommend these settings. As I have said before, it is not me that will be cornering hard in your car. You must decide the setting you use. I also fitted the brake pads into the callipers and the braided hoses to the side panel. I did have a little issue with the retaining spring on the brake pads. I couldn't find any information on how to assemble it, but eventually found a position that seemed logical, although it did keep shooting off.

I also fitted the brake pads into the callipers and the braided hoses to the side panel. I did have a little issue with the retaining spring on the brake pads. I couldn't find any information on how to assemble it, but eventually found a position that seemed logical, although it did keep shooting off.Friday, 9 November 2012

Off-side Panel

With the engine in place, the next job is fitting of the side panels before final fit of the front suspension.

With the engine in place, the next job is fitting of the side panels before final fit of the front suspension.As I had chosen to fit the back panel first, I knew that the side panels would probably not be a perfect fit where they meet the back panel at the rear wheels. A couple of minutes with the shears soon solved this.

To fix the side panels I have elected to only use rivets on the underside of the panel - where they can't be seen. Where the chassis meets the panel I have used "black glue". I am really impressed by this stuff and don't believe the panel will move at all once it is cured. Seen in the photo on the right is the first stage of the process. I will bend and fix the rear portion after freeing the clamps from the front, once it has dried.

To fix the side panels I have elected to only use rivets on the underside of the panel - where they can't be seen. Where the chassis meets the panel I have used "black glue". I am really impressed by this stuff and don't believe the panel will move at all once it is cured. Seen in the photo on the right is the first stage of the process. I will bend and fix the rear portion after freeing the clamps from the front, once it has dried.Engine - Part 4

GBS kindly sent the missing spacers and bolts via first class post. 36 hours later they turned up :-( Not GBS to blame, but our postal service which seems to be in steep decline..... but enough of that.

With the spacers and bolts supplied I bolted the engine mounts to the engine block and lowered the engine so that it just rested on the chassis but carried no weight. I had already mated the engine and gearbox and bolted them together once more.

The final step is to centre the engine in the chassis by marking the mid-point on a chassis cross member and aligning it with the centre of the nut on the flywheel. The position of the holes on the chassis plates for the engine mounting brackets was then marked and drilled to 8mm.

I found that one of the off-side bolts would have been too close to the chassis to get a nut on underneath so I drilled a new hole in the bracket and used that instead. My logic being that the slight weakening of the plate by drilling another hole was much less of an issue than leaving one bolt off altogether.

As the engine can be hoisted vertically using this method of installation it was simple to move it out of the way to drill the plates.

As the engine can be hoisted vertically using this method of installation it was simple to move it out of the way to drill the plates.

With the chassis plates drilled, it was now time to finally fit the engine and gearbox and torque up the bolts on the gearbox mount, prop shaft, gearbox casing and engine mounts (see Torque Settings). Finally with the side panels still off I fitted the started motor. Not the simple 5 minute job I thought. The top bolt is too close to the gearbox housing to tighten properly. After a few minutes filing down the rim of the nut head, it went in.

With the chassis plates drilled, it was now time to finally fit the engine and gearbox and torque up the bolts on the gearbox mount, prop shaft, gearbox casing and engine mounts (see Torque Settings). Finally with the side panels still off I fitted the started motor. Not the simple 5 minute job I thought. The top bolt is too close to the gearbox housing to tighten properly. After a few minutes filing down the rim of the nut head, it went in.

With the spacers and bolts supplied I bolted the engine mounts to the engine block and lowered the engine so that it just rested on the chassis but carried no weight. I had already mated the engine and gearbox and bolted them together once more.

The final step is to centre the engine in the chassis by marking the mid-point on a chassis cross member and aligning it with the centre of the nut on the flywheel. The position of the holes on the chassis plates for the engine mounting brackets was then marked and drilled to 8mm.

I found that one of the off-side bolts would have been too close to the chassis to get a nut on underneath so I drilled a new hole in the bracket and used that instead. My logic being that the slight weakening of the plate by drilling another hole was much less of an issue than leaving one bolt off altogether.

As the engine can be hoisted vertically using this method of installation it was simple to move it out of the way to drill the plates.

As the engine can be hoisted vertically using this method of installation it was simple to move it out of the way to drill the plates.  With the chassis plates drilled, it was now time to finally fit the engine and gearbox and torque up the bolts on the gearbox mount, prop shaft, gearbox casing and engine mounts (see Torque Settings). Finally with the side panels still off I fitted the started motor. Not the simple 5 minute job I thought. The top bolt is too close to the gearbox housing to tighten properly. After a few minutes filing down the rim of the nut head, it went in.

With the chassis plates drilled, it was now time to finally fit the engine and gearbox and torque up the bolts on the gearbox mount, prop shaft, gearbox casing and engine mounts (see Torque Settings). Finally with the side panels still off I fitted the started motor. Not the simple 5 minute job I thought. The top bolt is too close to the gearbox housing to tighten properly. After a few minutes filing down the rim of the nut head, it went in.

Wednesday, 7 November 2012

Engine - Part 3

Beautiful sunrise this morning.

I spoke to the guys at GBS yesterday about how to install an engine and gearbox on my own. There are two methods. The first is to mate the engine and gearbox and fit both as a single unit. This is difficult on your own but not impossible. The difficulty is the weight of the combined unit and manoeuvring it into the chassis opening whilst it dangles from the crane. The second is to fit them separately: the gearbox first and then the engine. The latter is simpler on your own because the gearbox can be positioned manually and the engine can go in almost vertically on the hoist.

I decided to fit them separately.

I decided to fit them separately.

First I needed to remove some gearbox casing from the base and bottom corner, and check that the clutch is aligned properly after fitting the spigot bearing. To do this I fitted the two spacers to the gearbox casing and mated the engine and gearbox, bolting it together so that it can be lifted as a single item. The engine spline slid straight into the gearbox and spigot without problem. With the unit dangling on my crane I marked the areas of the casing that needed to be removed.

First I needed to remove some gearbox casing from the base and bottom corner, and check that the clutch is aligned properly after fitting the spigot bearing. To do this I fitted the two spacers to the gearbox casing and mated the engine and gearbox, bolting it together so that it can be lifted as a single item. The engine spline slid straight into the gearbox and spigot without problem. With the unit dangling on my crane I marked the areas of the casing that needed to be removed. After a few minutes with my 9 inch angle grinder, both areas had been removed.

Next the gearbox mount must first be fitted. It requires a little reshaping first of all, followed by drilling the new mounting holes to 8mm. It is then installed from below - fully tightened and thread-locked.

Next the gearbox mount must first be fitted. It requires a little reshaping first of all, followed by drilling the new mounting holes to 8mm. It is then installed from below - fully tightened and thread-locked.

With the gearbox lifted from underneath with my trolley jack, I eased it into place on the mounting and finger tightened the 3 bolts to the prop shaft.

Now the gearbox is in place (approximately) the engine can be dropped in from above vertically. Having already ensured that the gearbox and engine go together easily, it didn't take long to drop the engine in and mate it with the gearbox once more. Quite straight forward really. Then I found the problem. I didn't have the fixing kit that connects the engine mounts either to the engine or the chassis plates. It was all going so well. As Newark is a 3 hour round trip, I called GBS and they kindly agreed to put the packs in the first class post - maybe tomorrow........Monday, 5 November 2012

Engine - Part 2

With the new sump assembled and ready, it was time to take the old one off - not that it had ever been used. First - drop the oil. As the temperature was only 4 degrees today it took a while. I thought about saving it for re-use, but it has been in there since 2004 so thought better of it. The filter took a bit of time to remove as its rubber seal had stuck to the engine block.

Removing the bolts holding the sump to the engine block is the not the whole story. Whilst these bolts form the uniform pressure across the gasket, in order to remove the sump there are 2 more bolts that need removing. These are only accessible if you remove the steel tray at the base of the sump. They hold the oil feeder pipe in position. Another thing I learned (the hard way - laying under an oil dripping engine block) was that these bolts have star and not hex heads.

Removing the bolts holding the sump to the engine block is the not the whole story. Whilst these bolts form the uniform pressure across the gasket, in order to remove the sump there are 2 more bolts that need removing. These are only accessible if you remove the steel tray at the base of the sump. They hold the oil feeder pipe in position. Another thing I learned (the hard way - laying under an oil dripping engine block) was that these bolts have star and not hex heads.

With the old sump finally off, I cleaned the sealant from the engine block and added new sealant to the outside rim of the new sump between the gasket and the edge of the machined surface. This should give that extra bit of protection. I then used a trolly jack to offer up the new sump to the block and bolted back in place.

With the old sump finally off, I cleaned the sealant from the engine block and added new sealant to the outside rim of the new sump between the gasket and the edge of the machined surface. This should give that extra bit of protection. I then used a trolly jack to offer up the new sump to the block and bolted back in place.

Removing the bolts holding the sump to the engine block is the not the whole story. Whilst these bolts form the uniform pressure across the gasket, in order to remove the sump there are 2 more bolts that need removing. These are only accessible if you remove the steel tray at the base of the sump. They hold the oil feeder pipe in position. Another thing I learned (the hard way - laying under an oil dripping engine block) was that these bolts have star and not hex heads.

Removing the bolts holding the sump to the engine block is the not the whole story. Whilst these bolts form the uniform pressure across the gasket, in order to remove the sump there are 2 more bolts that need removing. These are only accessible if you remove the steel tray at the base of the sump. They hold the oil feeder pipe in position. Another thing I learned (the hard way - laying under an oil dripping engine block) was that these bolts have star and not hex heads.

With the old sump finally off, I cleaned the sealant from the engine block and added new sealant to the outside rim of the new sump between the gasket and the edge of the machined surface. This should give that extra bit of protection. I then used a trolly jack to offer up the new sump to the block and bolted back in place.

With the old sump finally off, I cleaned the sealant from the engine block and added new sealant to the outside rim of the new sump between the gasket and the edge of the machined surface. This should give that extra bit of protection. I then used a trolly jack to offer up the new sump to the block and bolted back in place.Gearbox Prep

There are a few jobs that need doing to the gearbox before it is fitted to the engine block.

Firstly the pin to which the clutch actuator arm connects, needs to be replaced with the longer one supplied by GBS. This is a very simple procedure of knocking out the old one from the rear and tapping the new home into place with a wooden drift.

Next there is the fitting of the quick shift gear lever. Again a simple job. The linkage is held together by pin secured by a rubber washer and the mounting bracket by bolts to the gearbox housing (torgued to 45nm and threadlocked). Just need to make sure that the collar on the universal joint is adjusted so that all gears can be selected before everything is tightened up.

Firstly the pin to which the clutch actuator arm connects, needs to be replaced with the longer one supplied by GBS. This is a very simple procedure of knocking out the old one from the rear and tapping the new home into place with a wooden drift.

Next there is the fitting of the quick shift gear lever. Again a simple job. The linkage is held together by pin secured by a rubber washer and the mounting bracket by bolts to the gearbox housing (torgued to 45nm and threadlocked). Just need to make sure that the collar on the universal joint is adjusted so that all gears can be selected before everything is tightened up.

Raceline sump

The Raceline sump was a real pleasure to assemble. For a third party after-market product it is an extremely well made piece of engineering, even down to the flexible gasket which fits into a machined recess around the top.

The Raceline sump was a real pleasure to assemble. For a third party after-market product it is an extremely well made piece of engineering, even down to the flexible gasket which fits into a machined recess around the top.This is one of the only assembly jobs on the build so far where instructions are supplied. The trickiest bit is inserting the oil feed pipe once the rubber washers are in place. It is a really tight fit and difficult to push home. Other than that, the unit goes together very well. Here it is complete and semi wrapped before being put on one side awaiting its bolting to the engine block.

Spigot Bearing

In order to run a transverse engine in-line, a spigot bearing is required to be installed. To do this the clutch pressure plate and clutch need to be removed, before installing the bearing. The bearing needs to be tapped into place with a hammer and a wooden drift making sure that the finger bearings are at the back. Then re-install the clutch and pressure plates making sure the clutch plate is aligned properly.

Forget this small bearing and your gearbox is scrap within a few hours on the road.

Forget this small bearing and your gearbox is scrap within a few hours on the road.

Engine - Part 1

First to be removed was the fuel injectors and fuel rail, followed by the manifold itself.

You can see in the photo the cut-down manifold from GBS at the bottom of this picture. They have a jig to cut down the original inlet manifold to this size. I will return the old/full manifold back to GBS this week when I go up for a quick visit. I want to talk through the engine install before I start in earnest.

Each of the gaskets has to be transferred to the GBS cut-down version before it is installed once more along with the fuel rail and injectors.

Each of the gaskets has to be transferred to the GBS cut-down version before it is installed once more along with the fuel rail and injectors.The IAVC is also mounted on the old manifold. I have decided to remove it and try and use it with the Emerald ECU and the GBS prototype I purchased from Richard Lincoln. Richard originally bought it from GBS, but then decided to design and build his own. I am not going to do anything with it at the moment but will keep it ready for install when the time comes.

Here is the engine with the new manifold installed. I have taped up the inlets to prevent anything getting in there that shouldn't.

Finally, the exhaust manifold needs to be removed. I am not sure if GBS can recycle this in a similar way to the inlet manifold. I will take it up with me and find out. The heat shield can be re-used along with all of the fixings. Again I have taped the port openings. This photo also shows the installed GBS breather blanking plate which replaces the Ford breather unit.

Sunday, 21 October 2012

Rear Panel Complete

Work has been pretty hectic of late and has unfortunately eaten into my weekends, but this weekend I managed to spend a few hours in the garage. My focus was the back panel. It has been on and off a few times as I sorted out how it should fit and then how it should be fixed. This weekend I decided I had thought enough and it was time to do.

After finally figuring out that it was the distance between the bracing arms and the lower chassis that was the cause of my inability to make the panel fit correctly, I then focussed on the underside. I trimmed a few mm from the panel where it was touching the diagonal chassis members but that was it. I carefully marked the chassis position on the outside of the panel - double checked - triple checked and the drilled some pilot holes. When I was sure I had the correct position I very gingerly drilled the remaining holes in the panel and through the chassis powder coat only. As the fuel tank is so close, I removed the panel again to complete the drilling of the chassis and de-burr the panel.

After finally figuring out that it was the distance between the bracing arms and the lower chassis that was the cause of my inability to make the panel fit correctly, I then focussed on the underside. I trimmed a few mm from the panel where it was touching the diagonal chassis members but that was it. I carefully marked the chassis position on the outside of the panel - double checked - triple checked and the drilled some pilot holes. When I was sure I had the correct position I very gingerly drilled the remaining holes in the panel and through the chassis powder coat only. As the fuel tank is so close, I removed the panel again to complete the drilling of the chassis and de-burr the panel.

I followed a very similar procedure with the drilling of the rivet holes for the sides. With clecos in the already drilled base and the panel clamped in position, I marked and drilled the pilot holes, removing the panel again to complete the process. You will also notice from the photo the outline of the rear wheel arch which I very crudely applied so I didn't put any rivet holes in visible places where it wasn't necessary.

I followed a very similar procedure with the drilling of the rivet holes for the sides. With clecos in the already drilled base and the panel clamped in position, I marked and drilled the pilot holes, removing the panel again to complete the process. You will also notice from the photo the outline of the rear wheel arch which I very crudely applied so I didn't put any rivet holes in visible places where it wasn't necessary.

With the back panel now clecoed in place I then positioned the boot in-fill panels, marked and drilled these too for their fixing to the chassis only. Be careful drilling into the tubular chassis members. The drill bit can twist and shear if the drill is not pointing directly at the inner centre of the tube. That little piece of experience cost me two cobalt drill bits :-(

With all of the preparation complete it was time to open another tube of "black-glue". With a bead applied to all areas of the chassis where the back panel and boot in fill panels touched, I clecoed the panels back in position and got the riveter out.

With all of the preparation complete it was time to open another tube of "black-glue". With a bead applied to all areas of the chassis where the back panel and boot in fill panels touched, I clecoed the panels back in position and got the riveter out.

I left it to cure over night before marking and drilling the boot infill panels to the rear panel and the rear panel base to the rear panel sides. Then it was "black glue", clecos, and riveting to finish the fixing.

Back panel finally on and secured - another milestone.

Whilst concentrating on making sure I got the back panel right I missed one simple but important step. BEFORE FINAL FIXING OF THE REAR PANEL MAKE SURE YOU ROUTE THE WIRING LOOM FOR THE REAR LIGHTS THROUGH THE HOLES IN THE REAR PANEL. As I found out, if you try and do this afterwards - you can't. There is insufficient space between the rear panel and the tank. I had to remove the spade terminals from the wiring loom to get the wires through. I then needed to attach some more spade terminals. Not a big issue, but easily avoidable.

I had already cut down the rear lights so that they will sit at 90 degrees to the road, so with the re-assembled loom in place I attached the rear lights and the petrol filler cap. She's starting to look something like a car now - at least from the back.

I had already cut down the rear lights so that they will sit at 90 degrees to the road, so with the re-assembled loom in place I attached the rear lights and the petrol filler cap. She's starting to look something like a car now - at least from the back.

The next job on my list will be the engine preparation and fitting so I can finally get the side panels on. When I picked up the kit and got it home, I put the engine at the top of my garage - out of the way. Having now build the car in front of it, I can't get the hoist anywhere close to move it. So, it was time to put the wheels on and lower her carefully to the floor and out on to some tarmac for the very first time.

After finally figuring out that it was the distance between the bracing arms and the lower chassis that was the cause of my inability to make the panel fit correctly, I then focussed on the underside. I trimmed a few mm from the panel where it was touching the diagonal chassis members but that was it. I carefully marked the chassis position on the outside of the panel - double checked - triple checked and the drilled some pilot holes. When I was sure I had the correct position I very gingerly drilled the remaining holes in the panel and through the chassis powder coat only. As the fuel tank is so close, I removed the panel again to complete the drilling of the chassis and de-burr the panel.

After finally figuring out that it was the distance between the bracing arms and the lower chassis that was the cause of my inability to make the panel fit correctly, I then focussed on the underside. I trimmed a few mm from the panel where it was touching the diagonal chassis members but that was it. I carefully marked the chassis position on the outside of the panel - double checked - triple checked and the drilled some pilot holes. When I was sure I had the correct position I very gingerly drilled the remaining holes in the panel and through the chassis powder coat only. As the fuel tank is so close, I removed the panel again to complete the drilling of the chassis and de-burr the panel. I followed a very similar procedure with the drilling of the rivet holes for the sides. With clecos in the already drilled base and the panel clamped in position, I marked and drilled the pilot holes, removing the panel again to complete the process. You will also notice from the photo the outline of the rear wheel arch which I very crudely applied so I didn't put any rivet holes in visible places where it wasn't necessary.

I followed a very similar procedure with the drilling of the rivet holes for the sides. With clecos in the already drilled base and the panel clamped in position, I marked and drilled the pilot holes, removing the panel again to complete the process. You will also notice from the photo the outline of the rear wheel arch which I very crudely applied so I didn't put any rivet holes in visible places where it wasn't necessary. With the back panel now clecoed in place I then positioned the boot in-fill panels, marked and drilled these too for their fixing to the chassis only. Be careful drilling into the tubular chassis members. The drill bit can twist and shear if the drill is not pointing directly at the inner centre of the tube. That little piece of experience cost me two cobalt drill bits :-(

With all of the preparation complete it was time to open another tube of "black-glue". With a bead applied to all areas of the chassis where the back panel and boot in fill panels touched, I clecoed the panels back in position and got the riveter out.

With all of the preparation complete it was time to open another tube of "black-glue". With a bead applied to all areas of the chassis where the back panel and boot in fill panels touched, I clecoed the panels back in position and got the riveter out.I left it to cure over night before marking and drilling the boot infill panels to the rear panel and the rear panel base to the rear panel sides. Then it was "black glue", clecos, and riveting to finish the fixing.

Back panel finally on and secured - another milestone.

Whilst concentrating on making sure I got the back panel right I missed one simple but important step. BEFORE FINAL FIXING OF THE REAR PANEL MAKE SURE YOU ROUTE THE WIRING LOOM FOR THE REAR LIGHTS THROUGH THE HOLES IN THE REAR PANEL. As I found out, if you try and do this afterwards - you can't. There is insufficient space between the rear panel and the tank. I had to remove the spade terminals from the wiring loom to get the wires through. I then needed to attach some more spade terminals. Not a big issue, but easily avoidable.

I had already cut down the rear lights so that they will sit at 90 degrees to the road, so with the re-assembled loom in place I attached the rear lights and the petrol filler cap. She's starting to look something like a car now - at least from the back.

I had already cut down the rear lights so that they will sit at 90 degrees to the road, so with the re-assembled loom in place I attached the rear lights and the petrol filler cap. She's starting to look something like a car now - at least from the back.The next job on my list will be the engine preparation and fitting so I can finally get the side panels on. When I picked up the kit and got it home, I put the engine at the top of my garage - out of the way. Having now build the car in front of it, I can't get the hoist anywhere close to move it. So, it was time to put the wheels on and lower her carefully to the floor and out on to some tarmac for the very first time.

Subscribe to:

Comments (Atom)